CNC Machines Solutions & Automation Implementation

QST provides cutting-edge solutions for CNC machinery and industrial automation, tailored to meet the dynamic needs of modern manufacturing environments. Our offerings integrate precision engineering, smart control systems, and advanced robotics to enhance production efficiency, quality, and scalability.

Why QST:

-

Proven track record in turnkey CNC automation implementation.

-

Strong partnerships with top CNC and robotic brands.

-

Skilled team for mechanical, electrical, and PLC programming.

-

After-sales support with on-site & remote service.

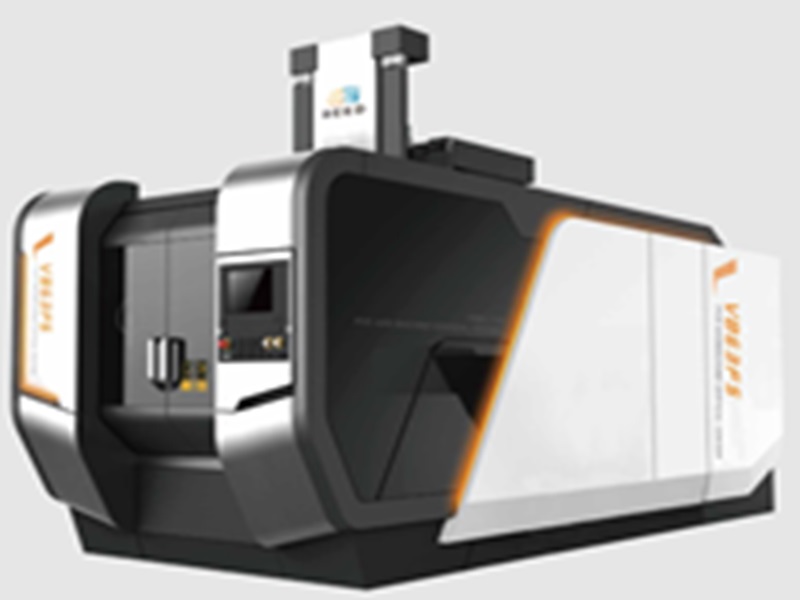

VL-Series Vertical Machining Center

This series machine adopts cross-slide structure, and equipped with roller linear guideway. It is mainly used for processing various small and medium-sized complex parts. It can complete milling, drilling, enlarging, tapping and contour milling with one clamping . It is suitable for processing various parts with high precision, multiple processing steps and complex shapes. After adding a CNC rotary table, the machine can have 4-axis/5-axis processing capabilities.

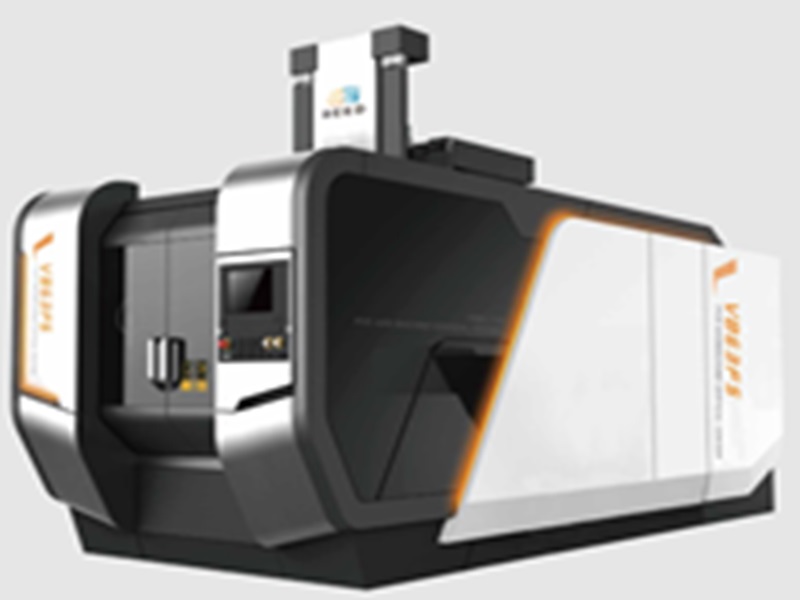

Vertical Machining Center

Moving parts such of the saddle, worktable, and spindle box adopt German advanced new steel plate welding technology, which can help increase rigidity ,reduce the motion inertia by moving parts weight reduction, meanwhile improve the response speed and moving accuracy.

GV Series Vertical Machining Center

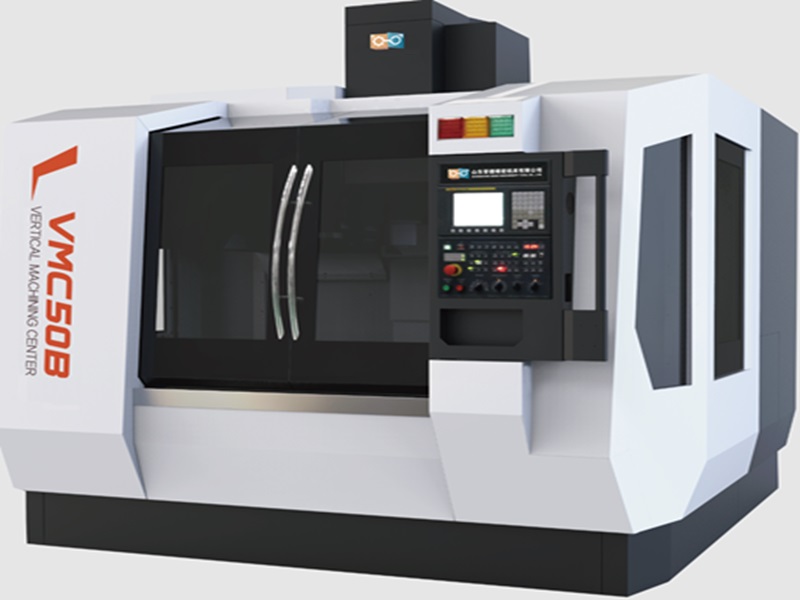

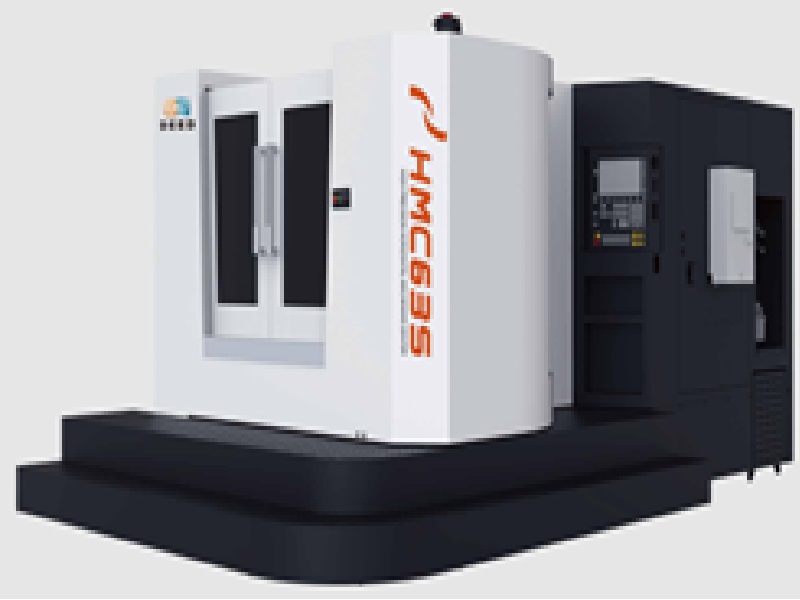

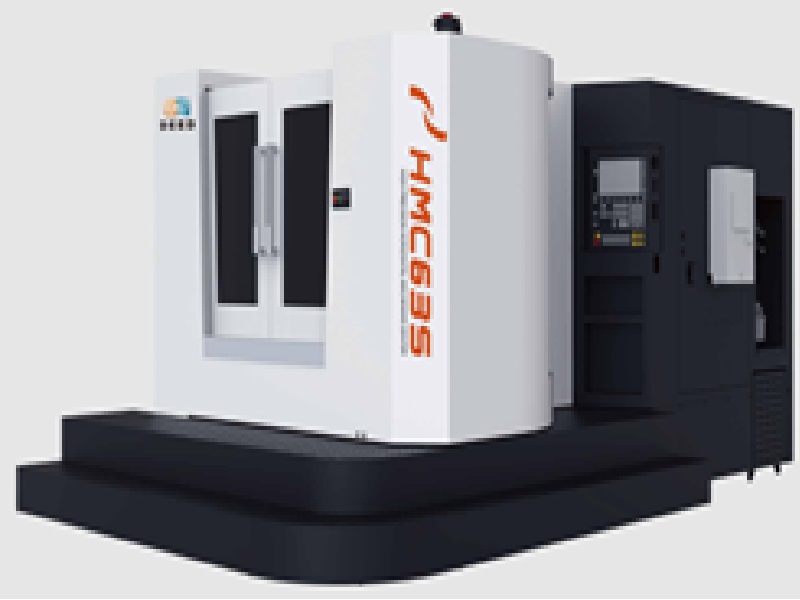

Horizontal Machining Center

This series of horizontal machining centers adopts inverted T-shape whole bed structure and portal double-wall column structure, configured with strong structural rigidity, large travel, and high precision, it can be widely used for various heavy cutting and high-precision mechanical processing industries. It can do milling, boring, drilling (drilling, expanding, reaming), tapping etc. and can meet single piece or small &medium batch products machining demands with high-efficient and high-precision.

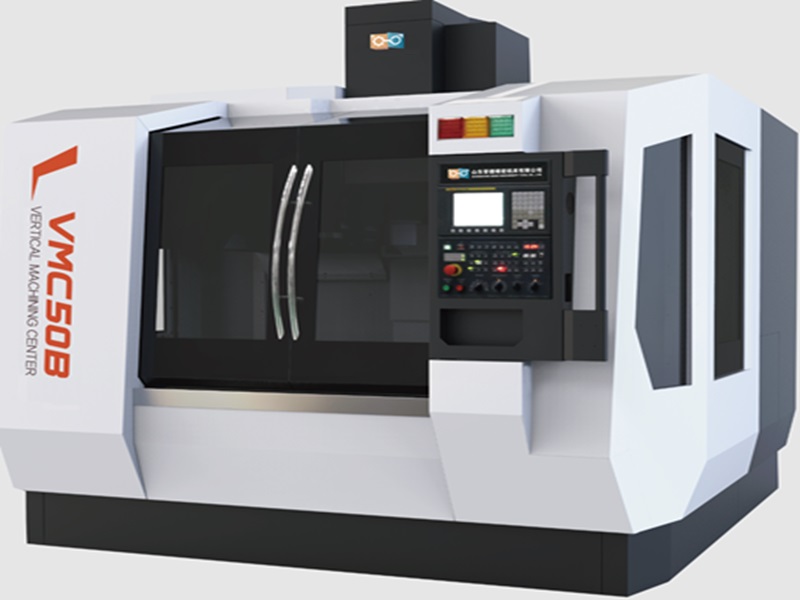

GL series Gantry Machining Center